Darkroom procedures in the X-ray department

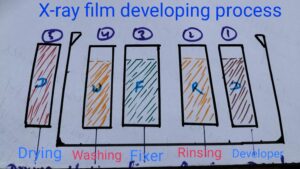

There are mainly five types of processes in a darkroom

1. Developer– Developing solution contain hydroquinone & metol ,sodium carbonate/sodium hydroxide, potassium bromide /iodide, sodium sulphite. Developing time 5 minutes, Temperature 20-22°C (68-72F°) Replenisher (hydroquinone + metol & alkali ) chemical uses when diminishes the developer.

2. Rinsing – Rinsing time 30 seconds to remove all traces (mark, object, sign) of the developing film & water must be circulating.

3. Fixer – chemical (hypo )–sodium thiosulphate-powdered form/ammonium thiosulphate-liquid form use to clear the film undeveloped /unexposed silver halide and sodium sulfite, chrome alum protects against it scratches sulphuric/ acetic acid use to neutralizes the alkali remaining on the film. Fixing time-1-4 minute ,temperature -18-24°C .

4. Washing – Washing water temperature 20°C, period of washing 20 minutes and temperature 20°C.

5. Drying – Drying in hot water temperature 35°C, drying cabinet very useful & film hang in a dust-free area. picture

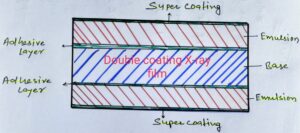

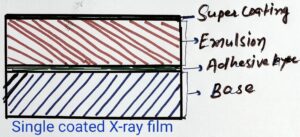

Film- X-Ray film is made of mainly two-part base & emulsion

- Base – base is made of cellulose triacetate & polyester.

- Adhesive layer

- Emulsion –made of gelatin &silver halide (95%silver bromide & 5% silver iodide

- Super coating – gelatin

X-ray film two type

- Single coated one side of film coated with emulsion.

- Double coated both sides of film coated with emulsion.

Note – Emulsion is the heart of the x-ray film

Illumination –Three types of illumination (decorating light)

1.Safelight –less than 15 watt

- General illumination –a source of overhead lighting use for general purposes.

- Radiographic illumination –Fluorescence illumination for viewing wet radiograph.

- Protection against Radiation in x-ray room – Wall is lead proof &, the floor is durable, easily cleaned not slippery, wall paint, varnish should be judged by safe light illumination, no any ventilation, the electric wire is proper maintenance, pass box near the film loading bench, pass box divided into two part one is exposed film other is unexposed film. Entrance single in darkroom and light-tight door with lead protected.

The special fact of x-ray room /darkroom you must have to know

- Darkroom is a special part of the hospital, nursing home, or private clinic it maintains safe illumination also called processing room

- The wall x-ray room should be lined with a lead sheet, a lead sheet thickness of 1.5 mm.

- A window should be avoided.

- Safelight to the film bench should not be less than 1.2 meters far.

- Bulb of safe light less than 15 watts.

- The emulsion is the heart of the x-ray film.

- The double-coated film is better than single coated.

- The emulsion is a mixture of silver halide & gelatin.

- Cassette is the rigid holder that contains intensifying screen & film, but in digital x-ray only intensifying screen contains.

- Cassette is made of low atomic number material like plastic /cardboard or aluminum should be thin and strong (not breakable).

- The intensifying screen is a device the converts the energy of light into visible light and the visible light interacts with radiographic film to form a latent image.

- more read …

I hope the guy’s like this post -Darkroom procedures in the x-ray department

Note – All the information through books and google search ….more information go google search and reputed books.

great post, very informative. I wonder why the other experts of this sector don’t notice this. You should continue your writing. I am confident, you’ve a huge readers’ base already!

Thanks